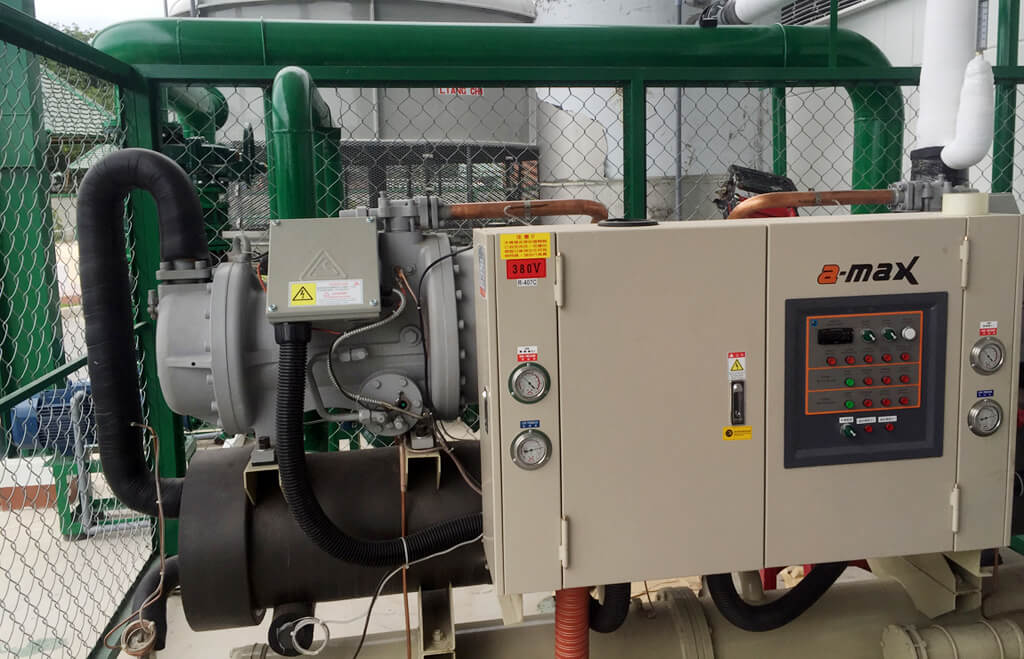

Supportive equipment of a-max can satisfy the heat pressure demands in the rubber industry, replacing conventional heating stove. Excellent a-max equipment can be applied to many industrial phases due to its high technology strengths, and can be applied to different production lines in the rubber industry. We dedicate to solve the technical issues of heating equipment that request for large amount of energy and customers can use our equipment to replace conventional electrical-based modes, delivering efficient and green methods of temperature reservation.

The die heater and cold water machines of a-max are used in many electric sectors as supportive temperature control equipment, such as in the area of wafer packaging and IC testing. With a good temperature controlling mechanism, manufacturers in the electric industry are able to achieve precision manufacturing process.

The materials of plastics are changing day by day. There are new and composite materials that are degradable items and are more environmentally friendly, and those new materials can replace existing plastics. This fact proves that human beings rely on plastics more and more.

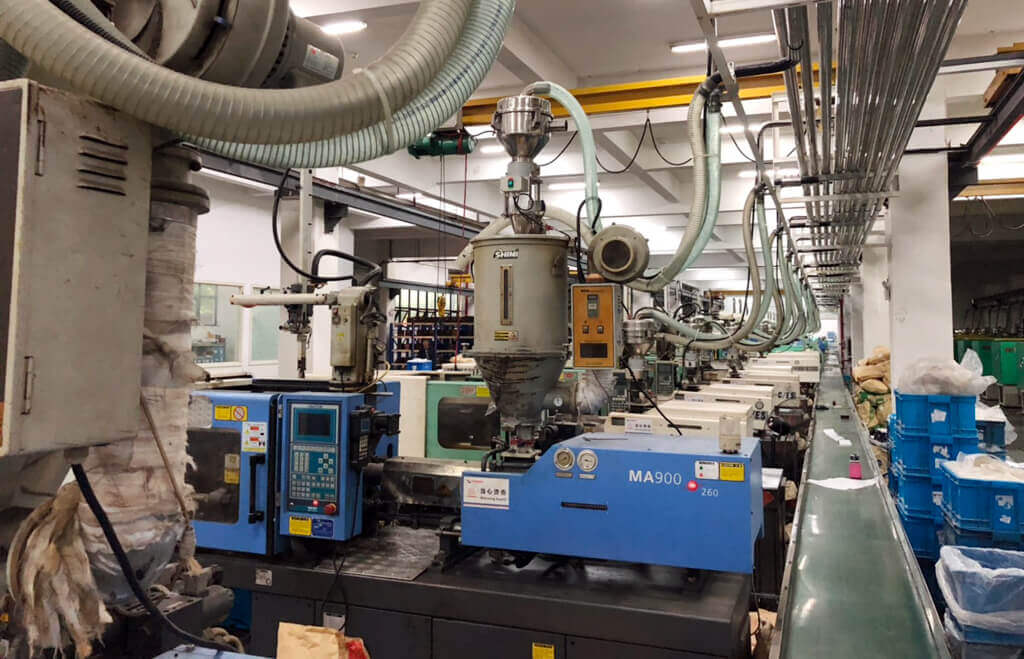

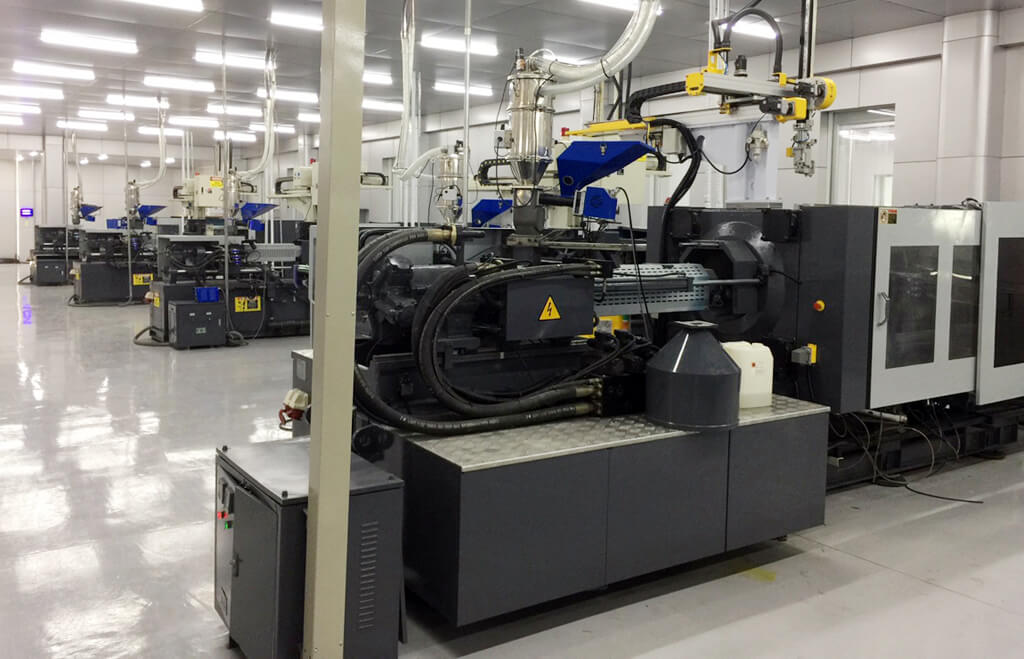

The supportive equipment of a-max help to stabilize manufacturing process, improving yield rates as well as productivity. At the same time, a-max equipment help reduce waste items. Moreover, a-max team dedicates to the field of plastics recycling and wants to contribute to the surrounding environment.

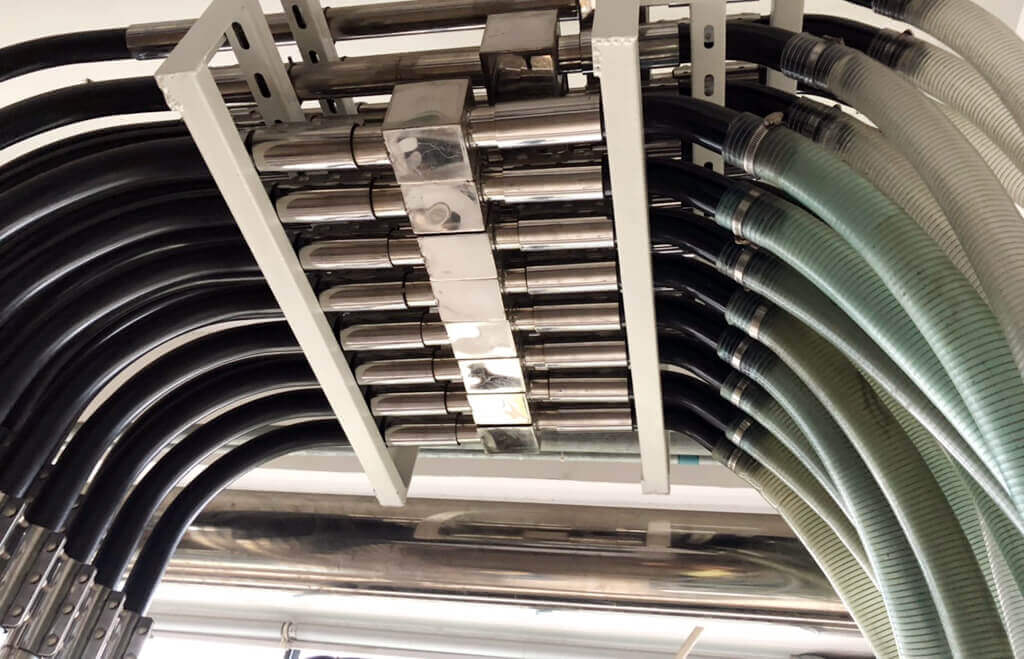

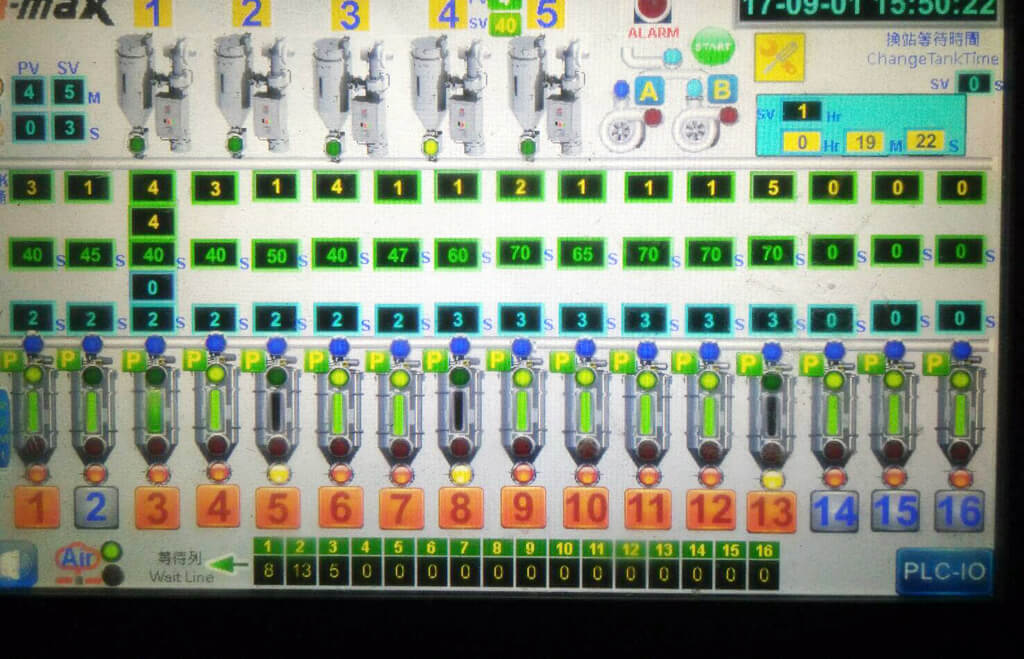

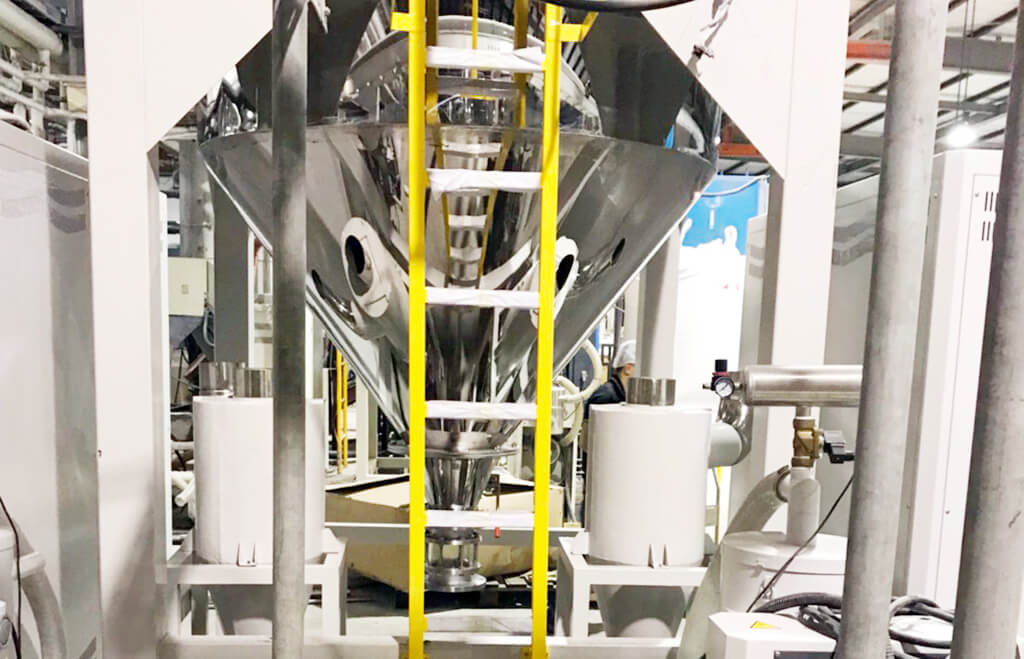

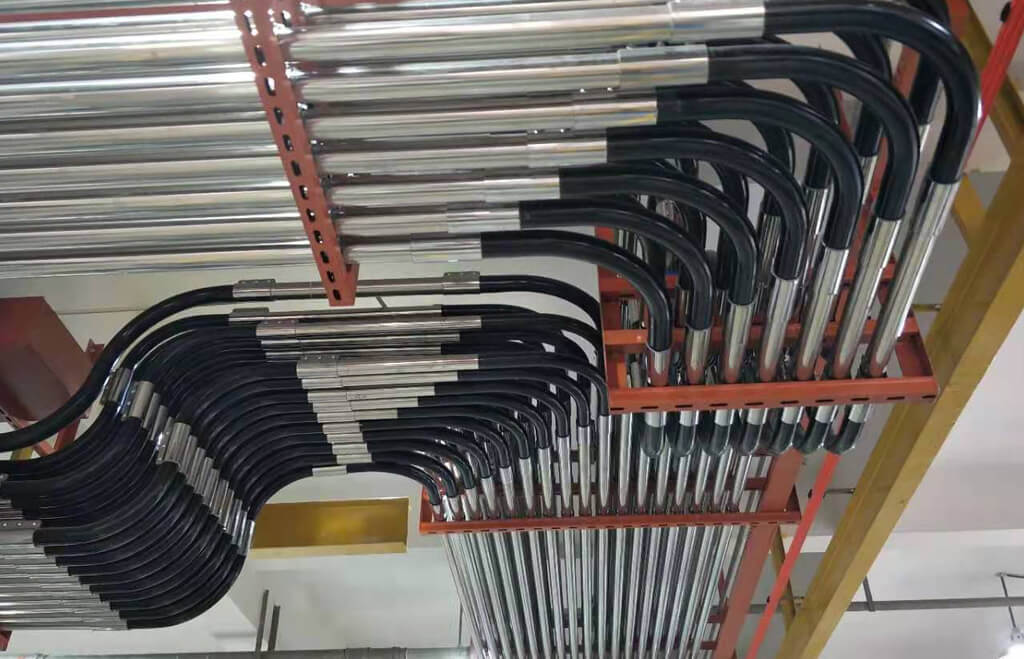

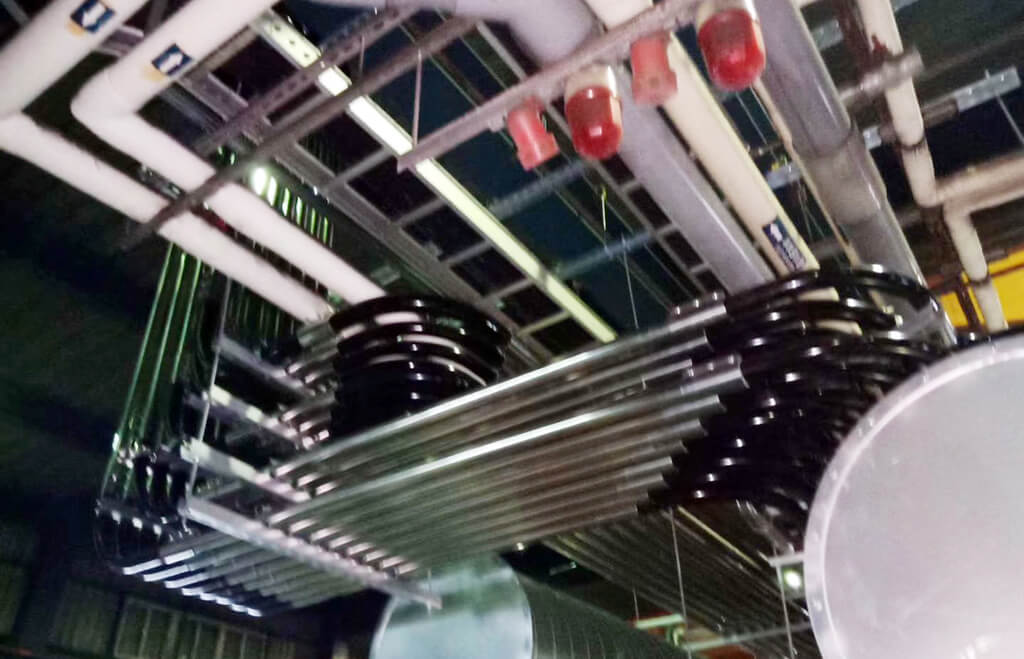

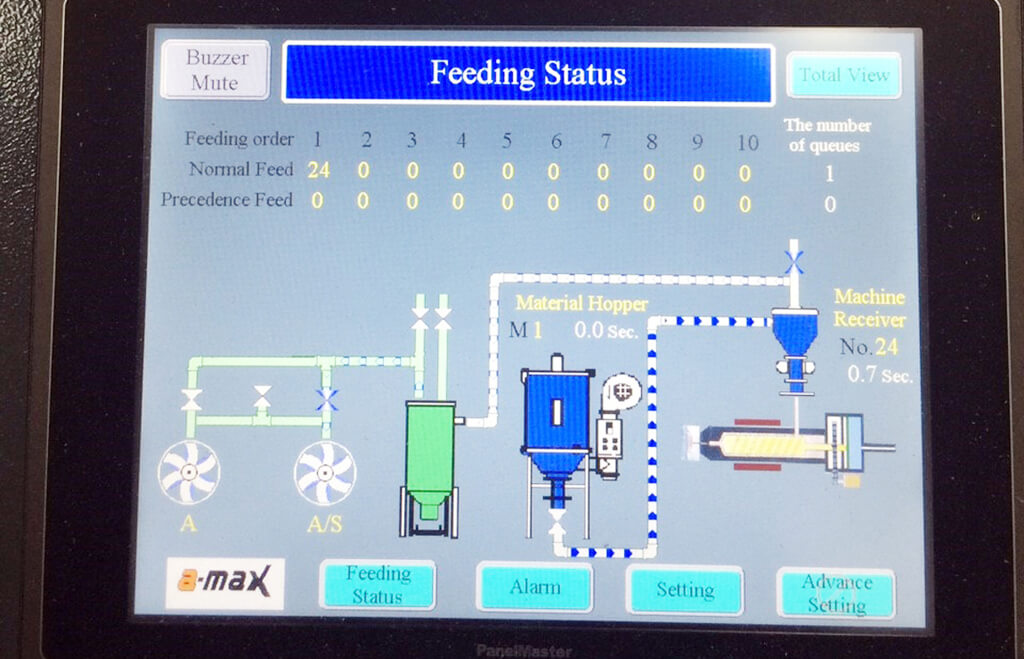

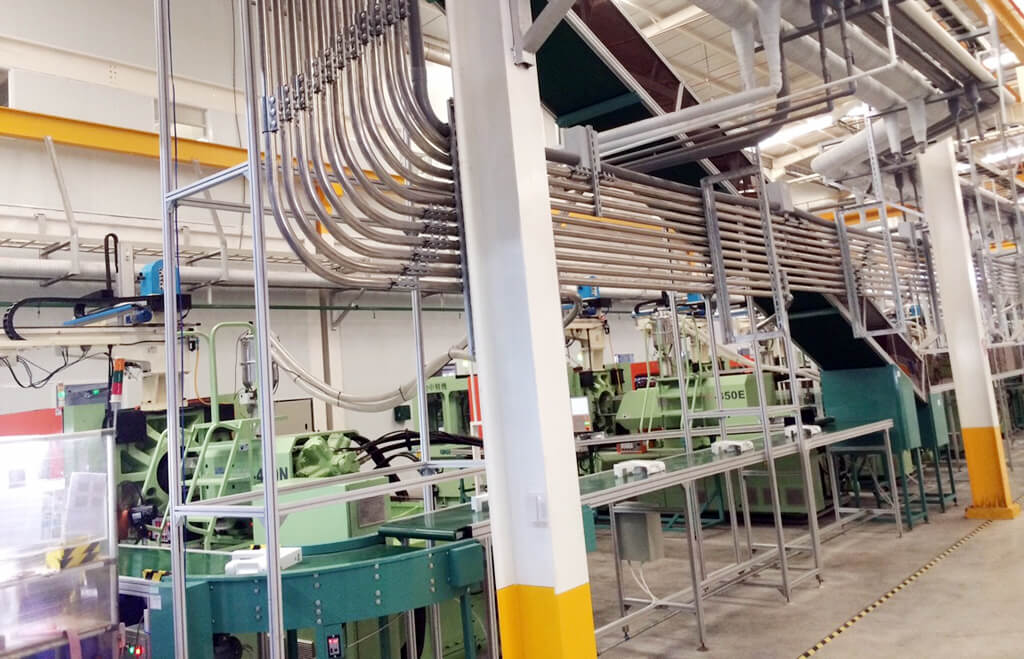

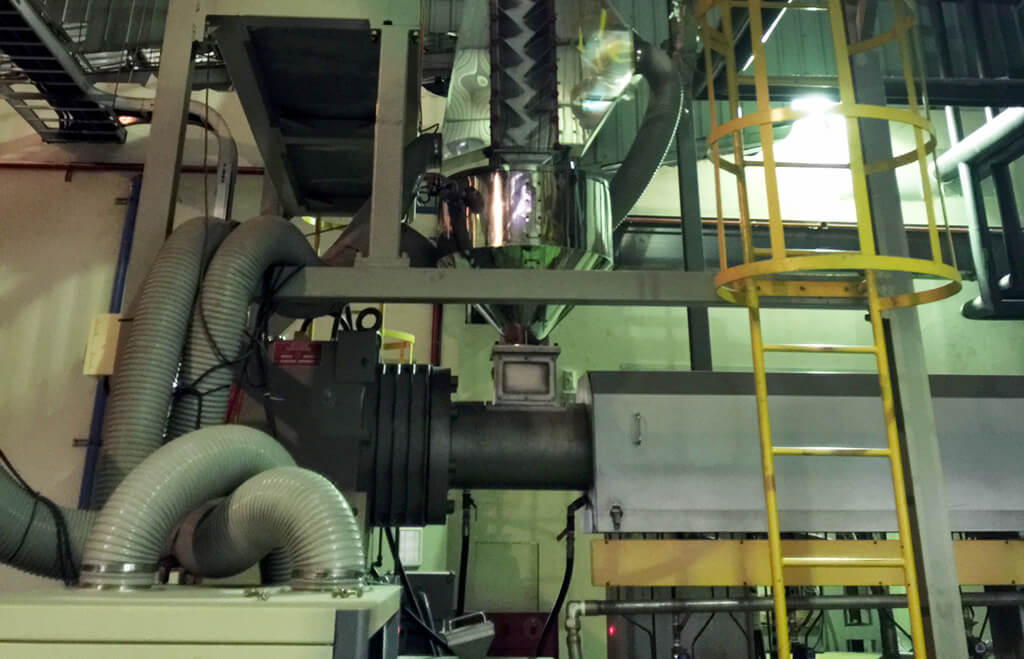

The system collects the cans that contains powders and dried raw materials caused by drying and heating processes as well as dehumidifier in the raw material room, so the entire plant can be much clean, beautiful, cooled, comfortable, management-friendly, manpower-saving, and management effective. Furthermore, our system integrates customers’ formula as well as mistake proofing.

PET materials with high translucent and high flexibility are widely applied in food utensil, construction material, exercise utility, etc. The application in the food container becomes the main stream. Among the many forming conditions, issues such as cleanliness, dryness, high flow rate, cooling capacity in lower temperature, de-dew after cooling, etc., are technologies with certain threshold level.

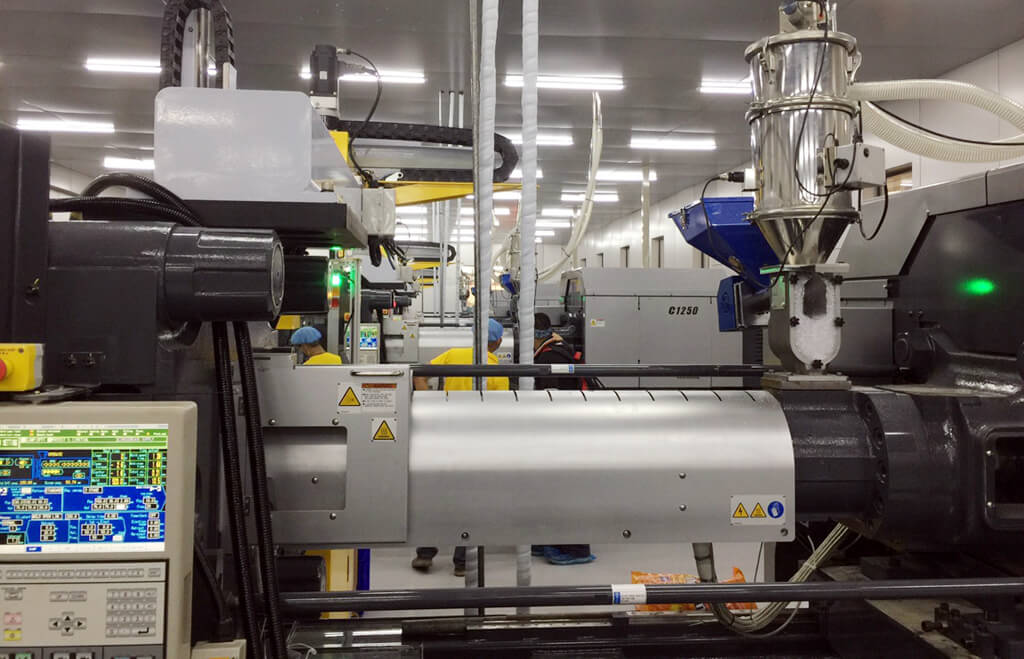

In the areas of both injection molding and extrusion, a-max is able to offer production line planning and technology R&D for customers.

In the sector of food container, a-max technology is able to provide high quality food containers in a wide variety to satisfy customers’ demands. The category ranges wide, including PET bottle, cooking oil can, cleaning liquid, candy can, packaging can, hand shake cup, bear cup, red wine cup, champagne cup, whisky cup, straw, food plate, microwave containers, temperature resistance PET food utensil, cup lid, knife, fork, etc.

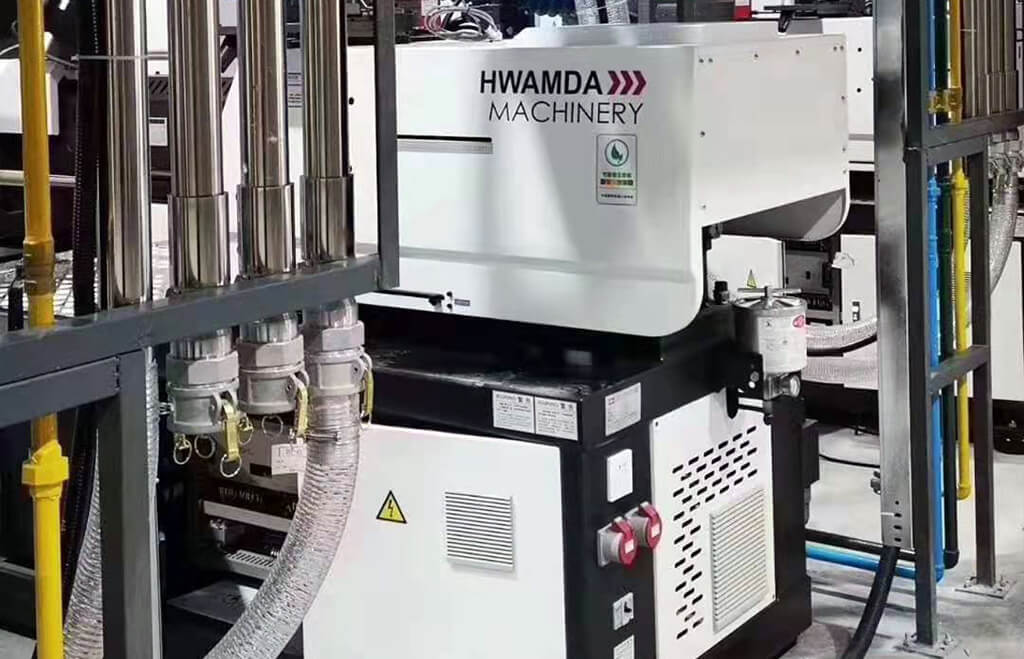

Besides production line planning, a-max also offers single machine option for customers, such as water-based/ oil-based temperature control equipment, water-based/ air-based cooling water machine/ oil cooling machine/ air cooling machine; multiple weighing color distribution/ resin distribution/ powder distribution; positive and negative pressure feeding/ powder feeding transmission equipment; wheel rotation/ double can dehumidifier; powder cleaning equipment; small-sized industrial RO equipment; energy-saving oxygen equipment for vehicle/ ship/ generator/ boiler items. Customers can choose those products for their best options.