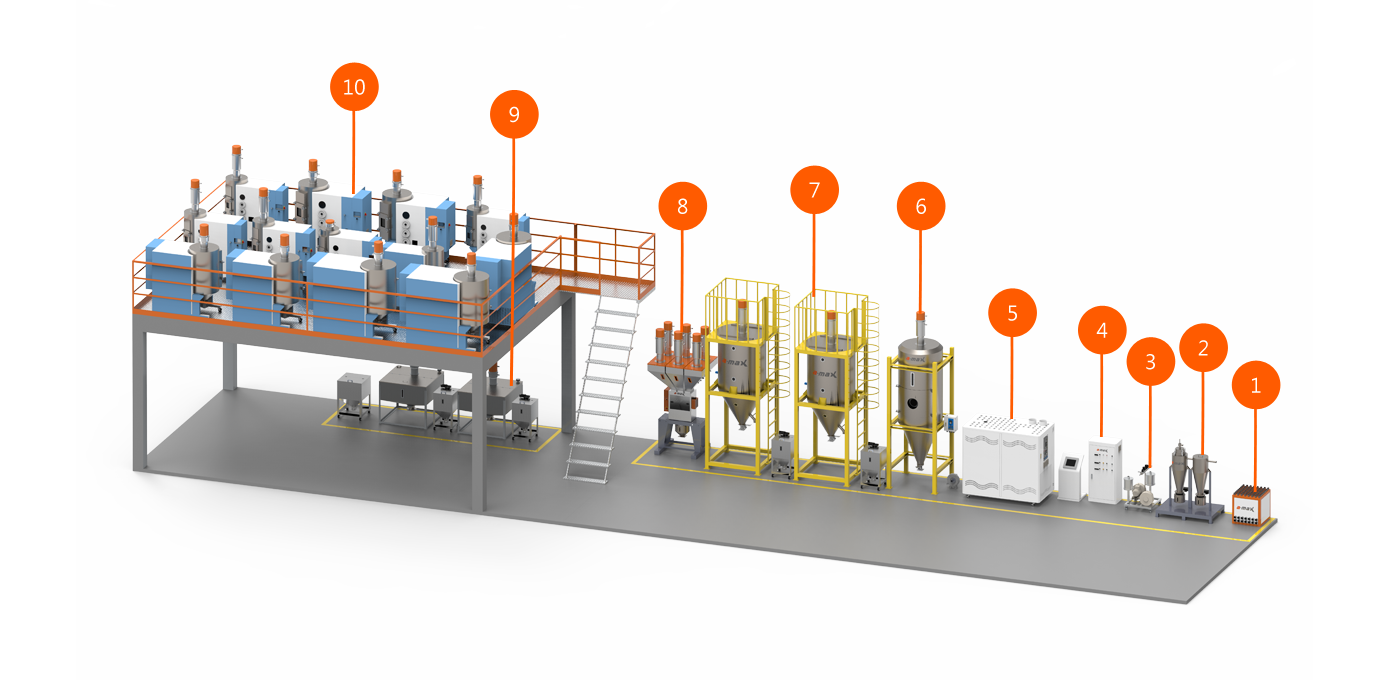

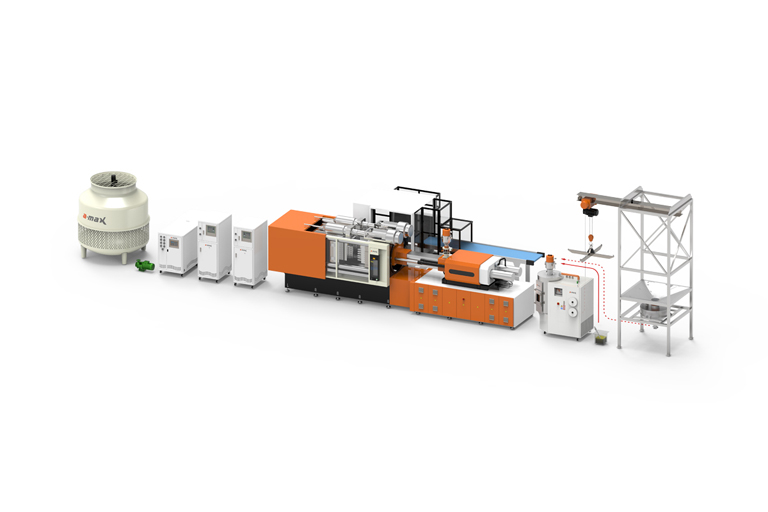

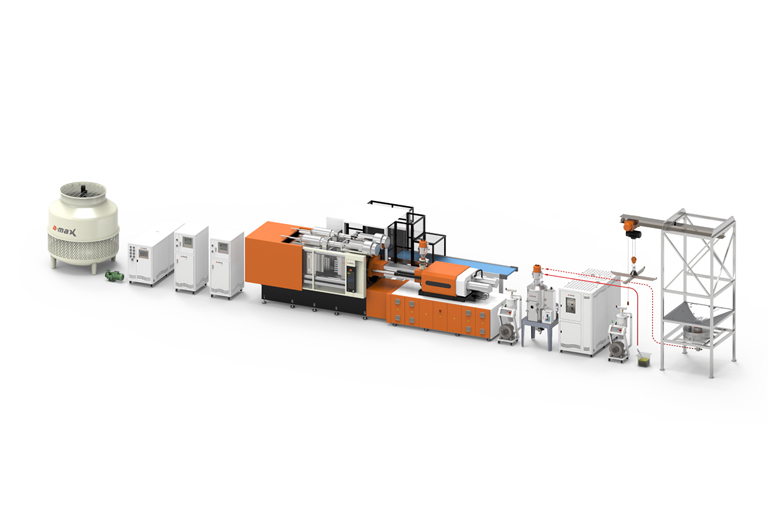

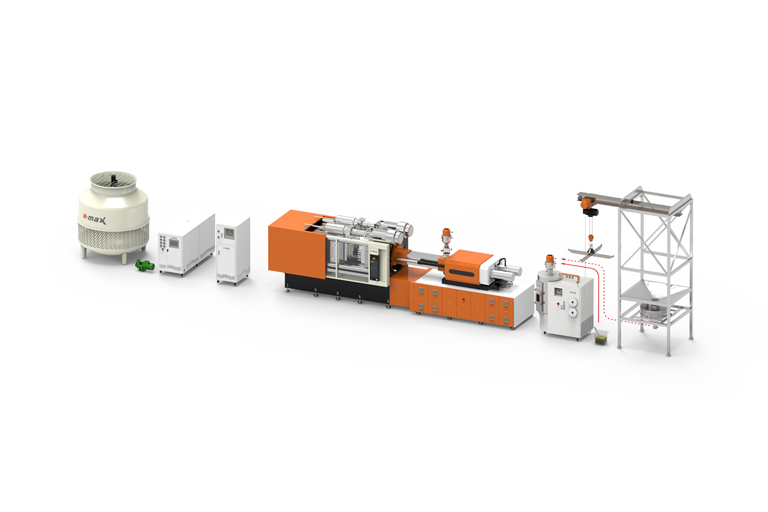

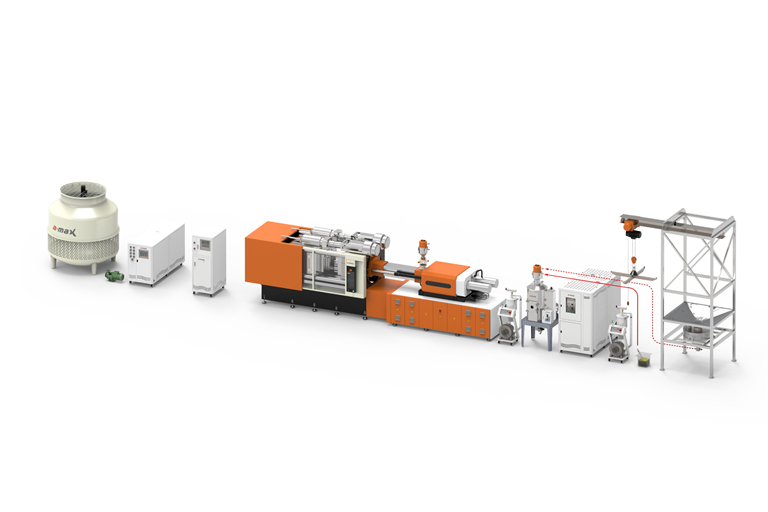

Plant Planning

The a-max team is a professional group with patient listeners. We know about customers’ demands based on their different manufacturing conditions, so we offer a wide variety of solutions for them to conquer their technical issues and our solution is able to fit into the corresponding regulations, granting them a comprehensive deal. Before each fieldwork visit, we do a lot of preparations so that we are able to know better about customers’ production lines of rubber and plastics items.

Service Procedures

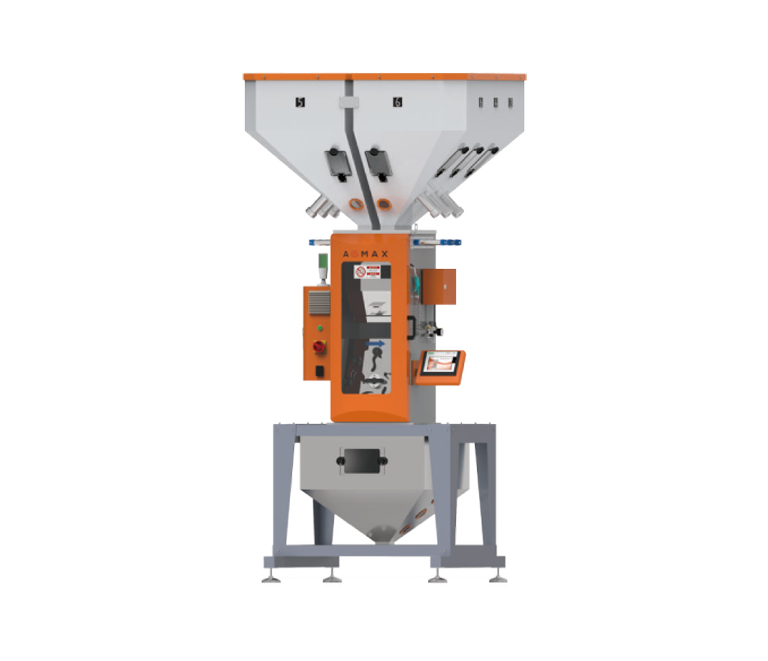

Before we visit your plant, we will do study and a thorough investigation about your product items, category, materials, etc. Based on our information gained in the process, we are able to know about how to do in order to achieve your goals with practical methods. We offer appropriate supportive equipment solutions after we finished listening your demands. The a-max team customizes products based on buyers’ needs and offers professional supportive systems.

Service Procedures Diagrams

Before we visit you

Before we visit your plants

Production line planning

Before we visit you

- We need to know about customers’ industrial sectors

- We need to know about customers’ end products

Before we visit your plants

- We listen to our customers about what they need

- We visit customers’ plants and production lines

- We study customers’ rubber and plastics materials and propose the optimal solutions for them

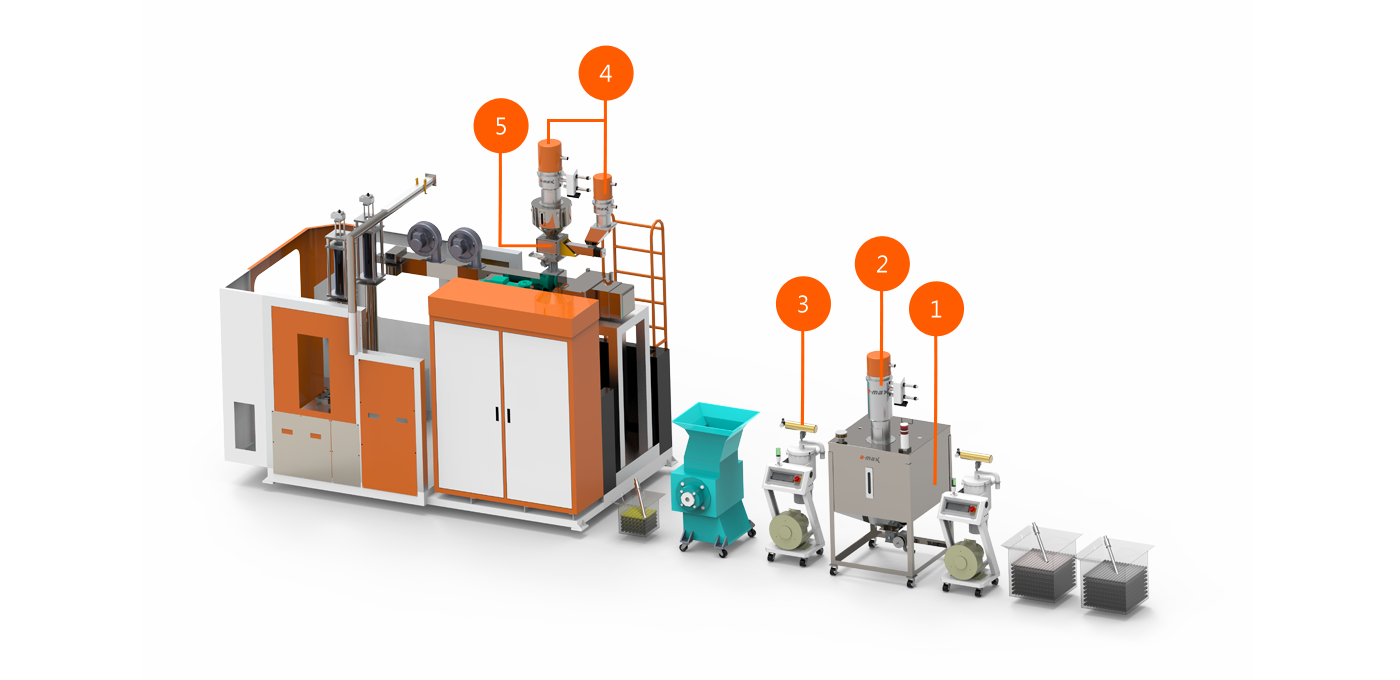

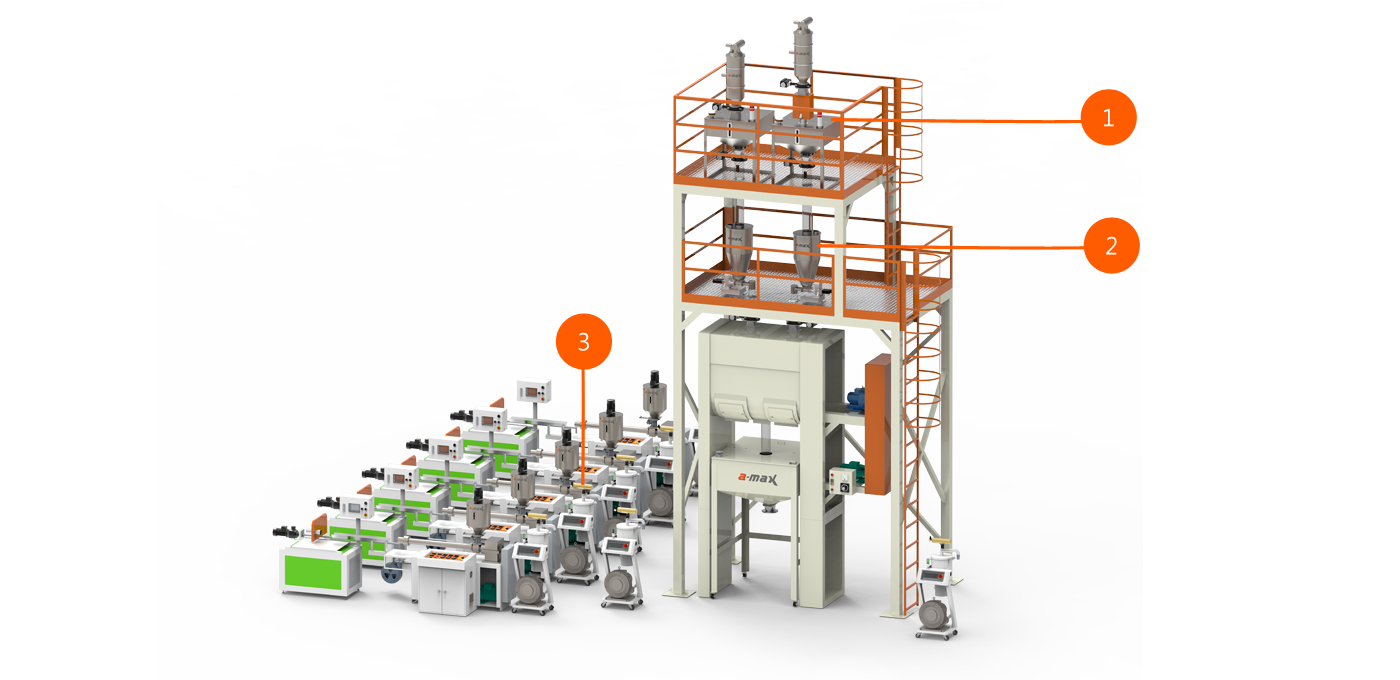

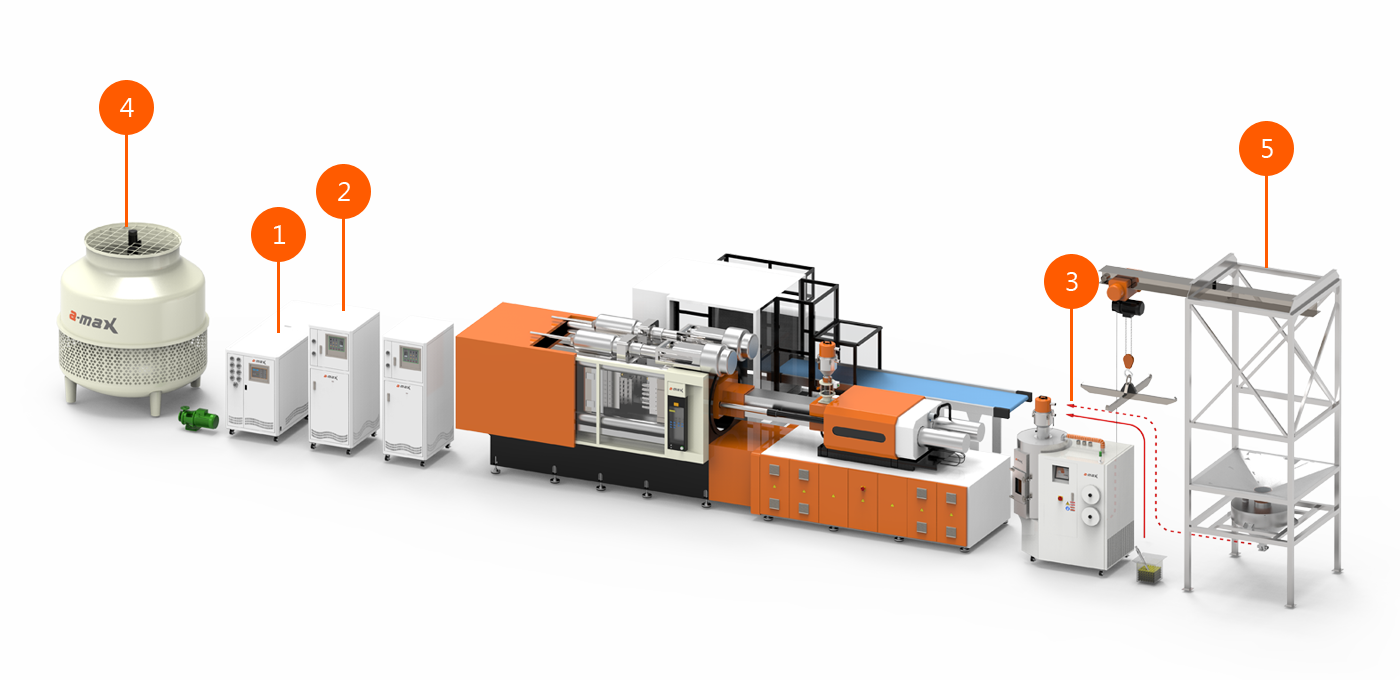

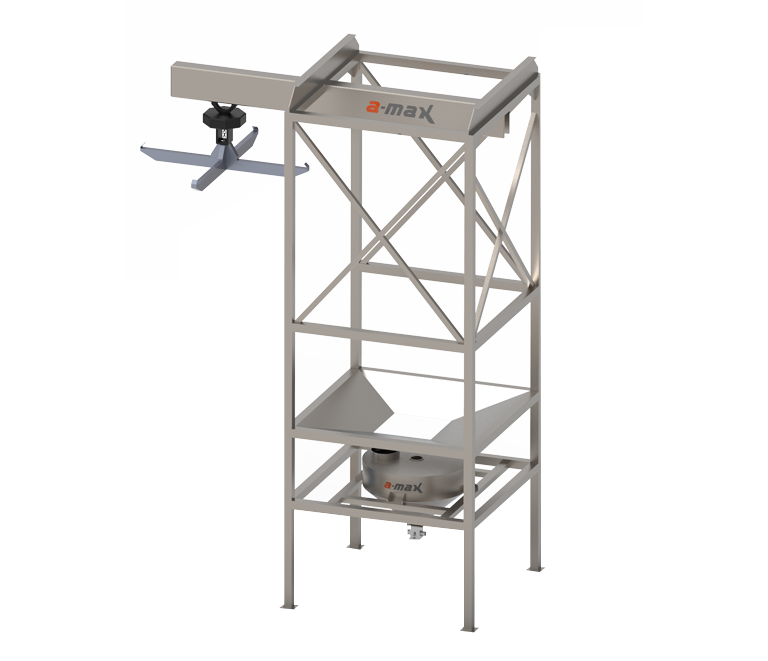

Production line planning

- First of all, we propose our prepared project and describe the planned position and operator mobility

- Proposing alternative projects based on customers’ choices and making adjustments

- In the end, we will decide the practical solution.

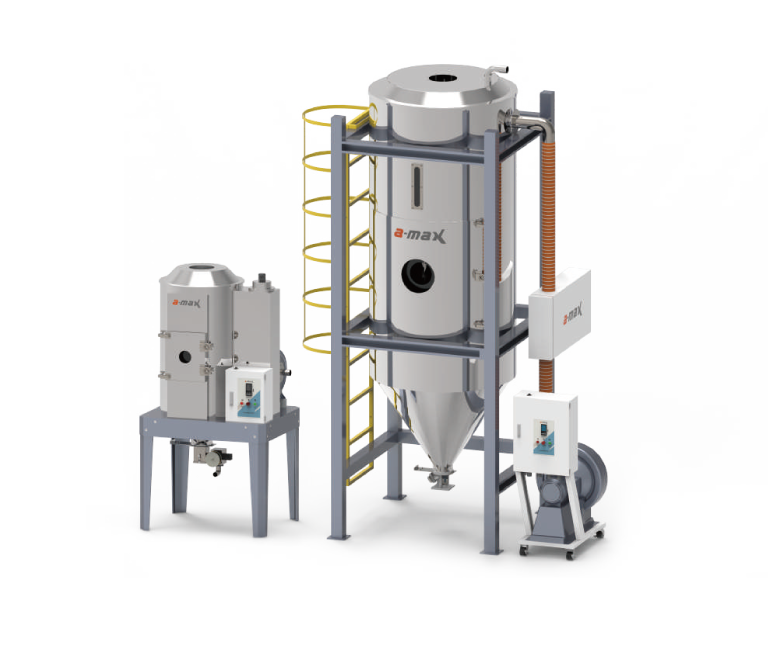

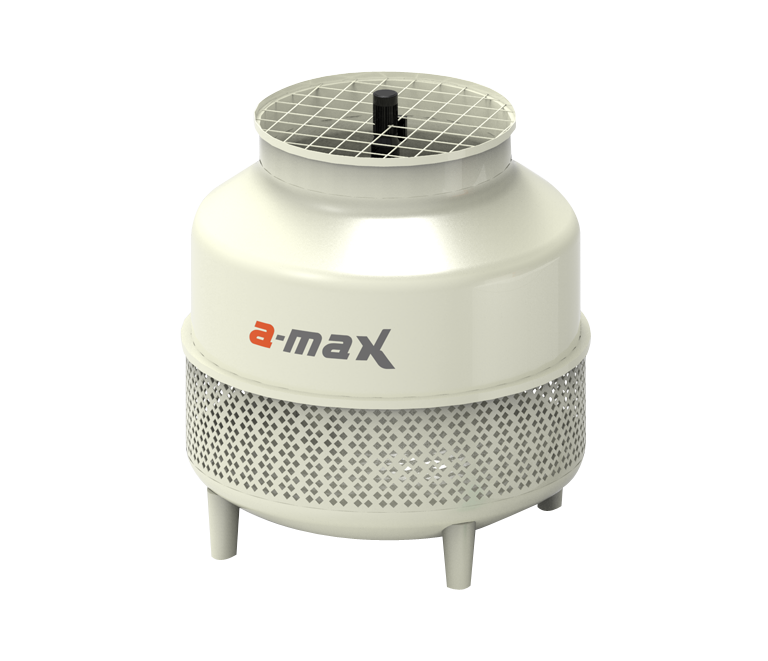

Plastics Industry

食品容器

生技醫療