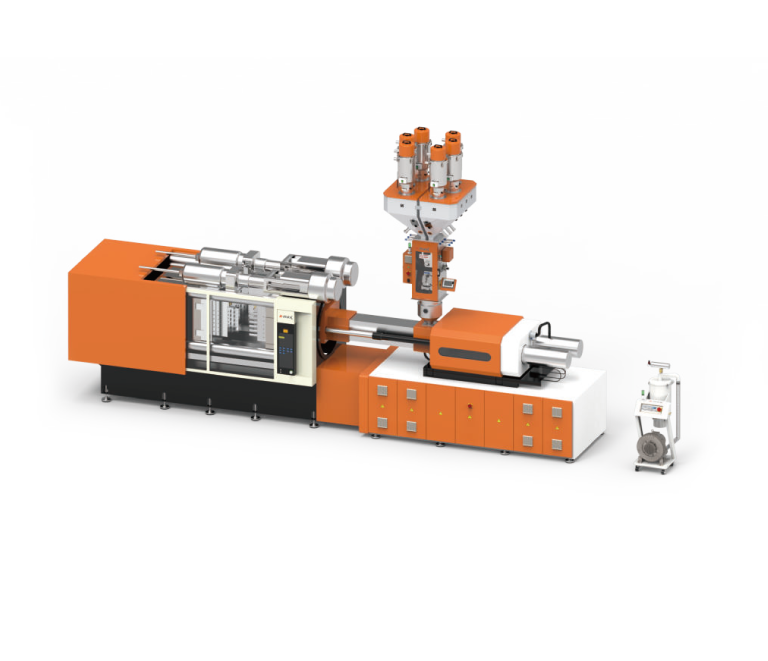

Dosing And Mixing Blender

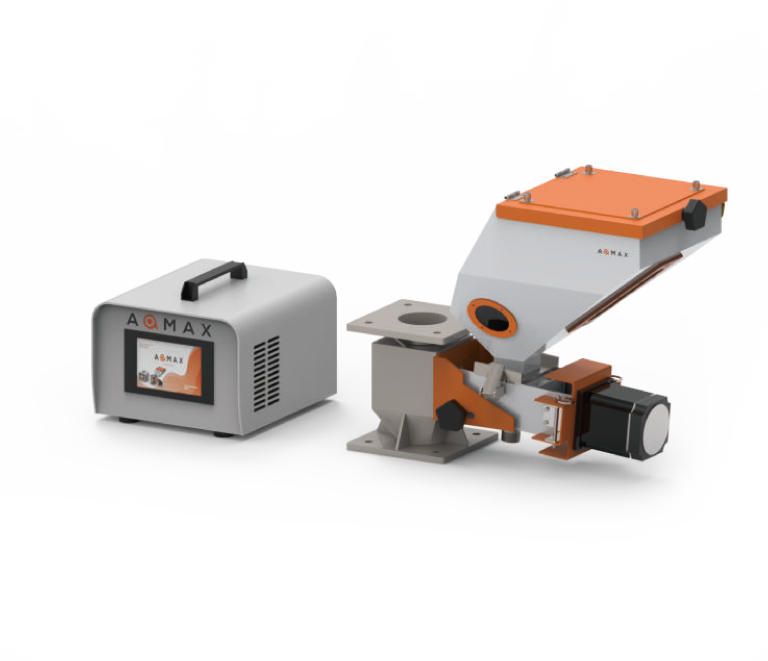

Auto Master-Batch Doser MD Series

Dosing And Mixing Blender

Auto Master-Batch Doser MD Series

Auto Master-batch Doser

- 10 parameter & formula memory to permanently store output time and weight.

- Modular design for easy assembly, disassembly, cleaning, and material change.

- Pigment storage tank with material shortage warning device.

- PLC and HMI enable easy operation, automatic calculation, adjustable processing speeds to ensure consistent output pigment proportion.

- In the case of a sudden blackout, in-process operations are memorized, and will immediately resume measurement upon restart.

- SUS340 screw rod is durable, rustproof, and will not contaminate material.

- Step-motor-driven measuring screw rod to ensure precise, stable adding of pigment.

- Forced material ejection to enable convenient pigment change.

- The extrusion MDE series are of RPM synchronization adjustment design. When the extrusion amount changes, it can synchronously execute the automatic adjustment function to keep the color consistency.

- The injection DI series: optional control by injection machine 0-10V connection signal or metering time to avoid errors caused by different injection time of the injection machine.

Machine Colors

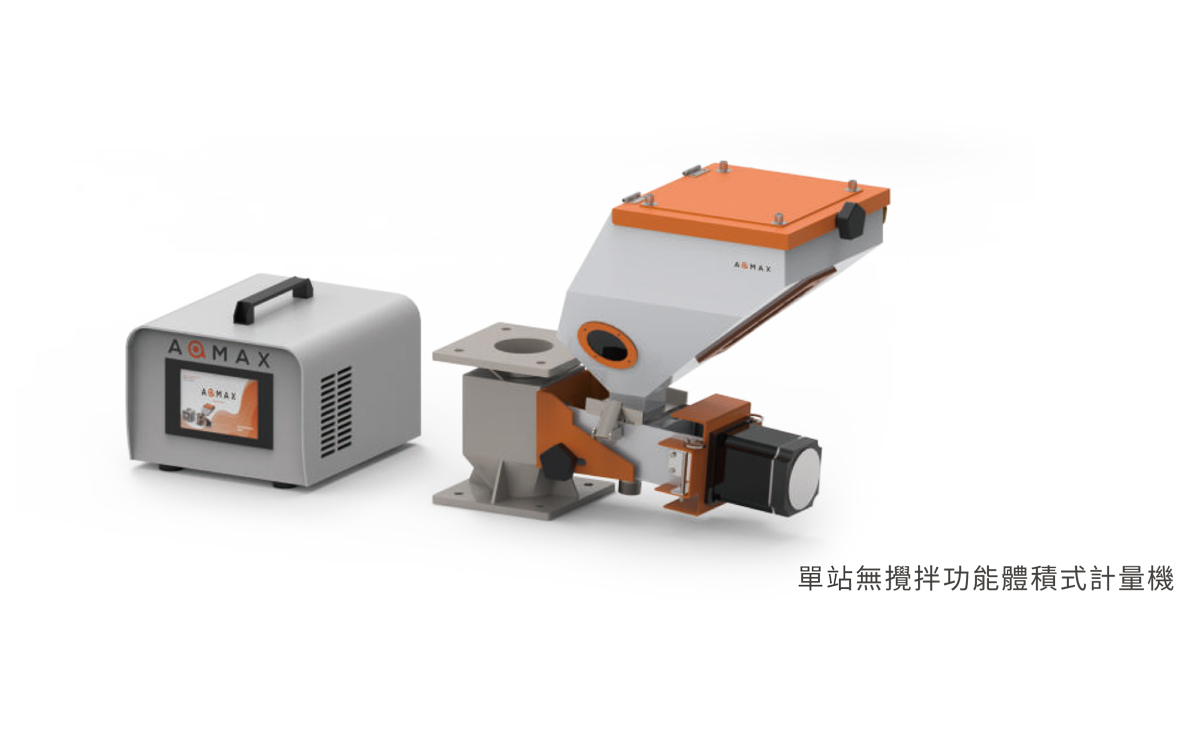

Single Color Auto Master-batch Doser

Model

| Motor Power | w |

| Motor Speed | rpm |

| Stir Power | w |

| Screw Model | |

| Output | kg/h |

| Storage Tank | l |

| Reduction Ratio | |

| Dimension (W x D x H) (With Standard Base) |

mm |

| Approx. Weight | kg |

MD30-08S

| 30 |

| 3000 |

| 90 * |

| 8 |

| 0.08-1.5 |

| 12 |

| 30 |

| 550 x 295 x 420 |

| 17 |

MD30-12

| 30 |

| 3000 |

| 90 * |

| 12 |

| 0.1-3 |

| 12 |

| 30 |

| 550 x 295 x 420 |

| 17 |

MD30-16

| 30 |

| 3000 |

| 90 * |

| 16 |

| 0.2-10 |

| 12 |

| 30 |

| 550 x 295 x 420 |

| 17 |

MD30-20

| 30 |

| 3000 |

| 90 * |

| 20 |

| 0.4-20 |

| 12 |

| 30 |

| 550 x 295 x 420 |

| 17.5 |

MD30-20S

| 30 |

| 3000 |

| 90 * |

| 20S |

| 0.8-30 |

| 12 |

| 30 |

| 550 x 295 x 420 |

| 17.5 |

MD30-24

| 30 |

| 3000 |

| 90 * |

| 24 |

| 0.8-38 |

| 12 |

| 30 |

| 550 x 295 x 420 |

| 17.5 |

MD30-24S

| 30 |

| 3000 |

| 90 * |

| 24S |

| 1.5-60 |

| 12 |

| 30 |

| 550 x 295 x 420 |

| 18 |

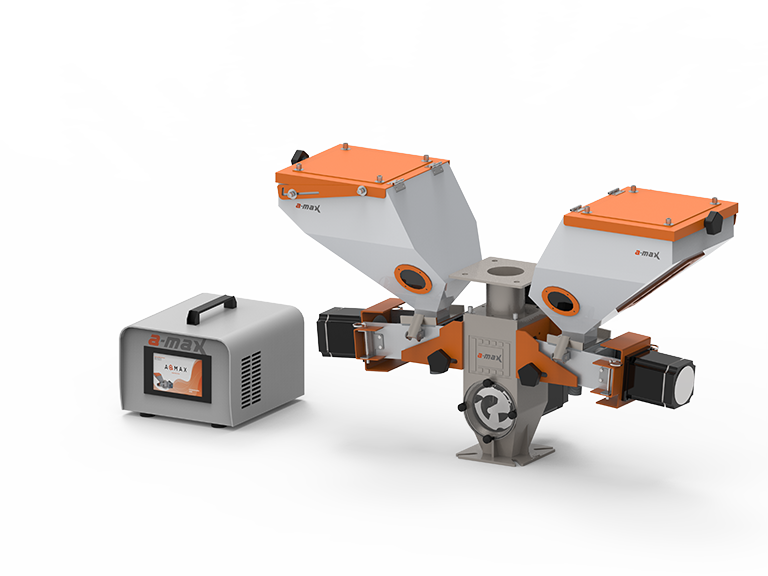

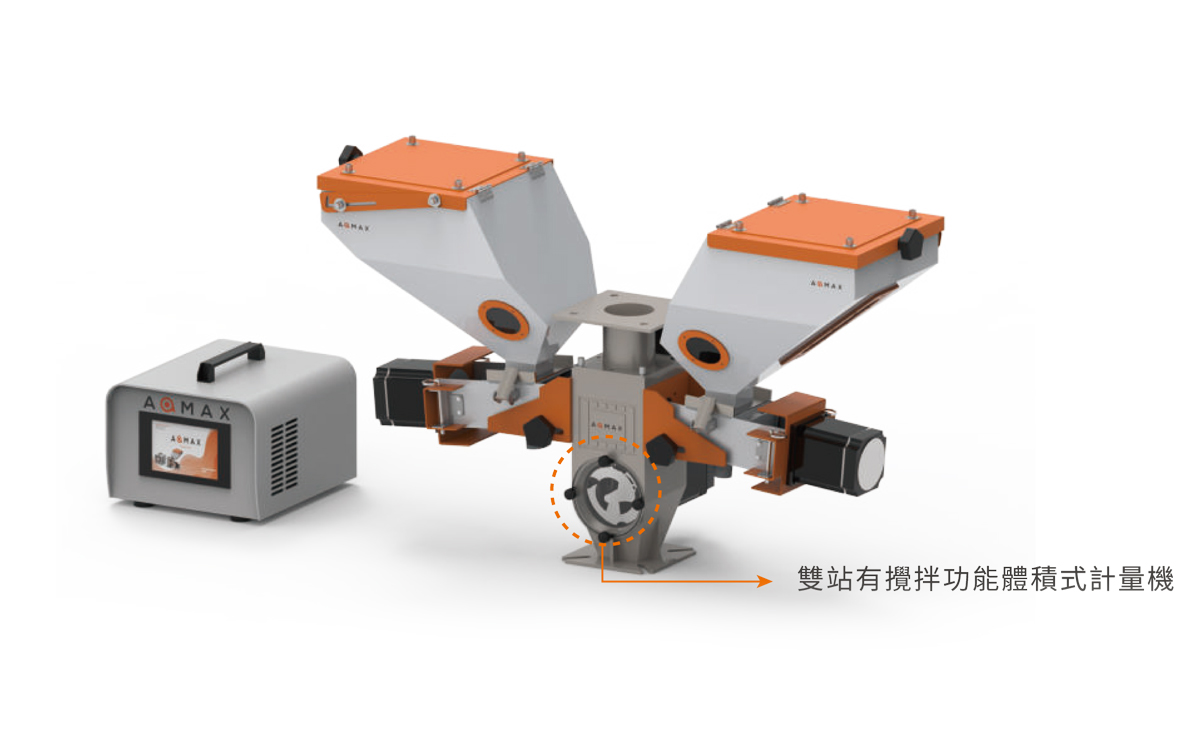

Dual Color Auto Master-batch Doser

Model

| Motor Power | w |

| Motor Speed | rpm |

| Stir Power | w |

| Screw Model | |

| Output | kg/h |

| Storage Tank | l |

| Reduction Ratio | |

| Dimension (W x D x H) (With Standard Base) |

mm |

| Approx. Weight | kg |

MD-D30/30

| 30 x 2 |

| 3000 |

| 90 * |

| 30 / 30 |

| 20-90 |

| 12 x 2 |

| 30 / 30 |

| 930 x 295 x 420 |

| 30 |

MD-D30/50

| 30 x 1 / 50 x 1 |

| 3000 |

| 90 * |

| 30 / 50 |

| 30-125 |

| 12 x 1 / 30 x 1 |

| 30 / 50 |

| 930 x 295 x 420 |

| 30.5 |

MD-D50/50

| 50 x 2 |

| 3000 |

| 90 * |

| 50 / 50 |

| 40-160 |

| 30 x 2 |

| 50 / 50 |

| 930 x 295 x 420 |

| 31 |

Triple Color Auto Master-batch Doser

Model

| Motor Power | w |

| Motor Speed | rpm |

| Stir Power | w |

| Screw Model | |

| Output | kg/h |

| Storage Tank | l |

| Reduction Ratio | |

| Dimension (W x H x D) (With Standard Base) |

mm |

| Approx. Weight | kg |

MD-D30/30/30

| 30 x 3 |

| 3000 |

| 90 * |

| 30 / 30 / 30 |

| 60-135 |

| 12 x 3 |

| 30 / 30 / 30 |

| 930 x 930 x 420 |

| 43 |

MD-D30/42/30

| 30 x 2 + 50 x 1 |

| 3000 |

| 90 * |

| 30 / 42 / 30 |

| 40-170 |

| 12 x 3 |

| 30 / 50 / 30 |

| 930 x 930 x 420 |

| 44 |

MD-D30/42/42

| 30 x 1 + 50 x 2 |

| 3000 |

| 90 * |

| 30 / 42 / 42 |

| 50-205 |

| 12 x 3 |

| 30 / 50 / 50 |

| 930 x 930 x 420 |

| 44.5 |

MD-D42/42/42

| 50 x 3 |

| 3000 |

| 90 * |

| 42 / 42 / 42 |

| 60-240 |

| 12 x 3 |

| 50 / 50 / 50 |

| 930 x 550 x 420 |

| 45 |

MD-D42/42/50

| 50 x 3 |

| 3000 |

| 90 * |

| 42 / 42 / 50 |

| 60-240 |

| 12 x 2 / 30 x 1 |

| 50 / 50 / 50 |

| 930 x 550 x 420 |

| 45.5 |

MD-D42/50/50

| 50 x 3 |

| 3000 |

| 90 * |

| 42 / 50 / 50 |

| 60-240 |

| 12 x 1 / 30 x 2 |

| 50 / 50 / 50 |

| 930 x 930 x 420 |

| 46 |

MD-D50/50/50

| 50 x 3 |

| 3000 |

| 90 * |

| 50 / 50 / 50 |

| 60-240 |

| 30 x 3 |

| 50 / 50 / 50 |

| 930 x 930 x 420 |

| 46.5 |

※ Continual masterbatch in 1.2kg/L, packing density calculation of these models adopts 2-3mm(dia).

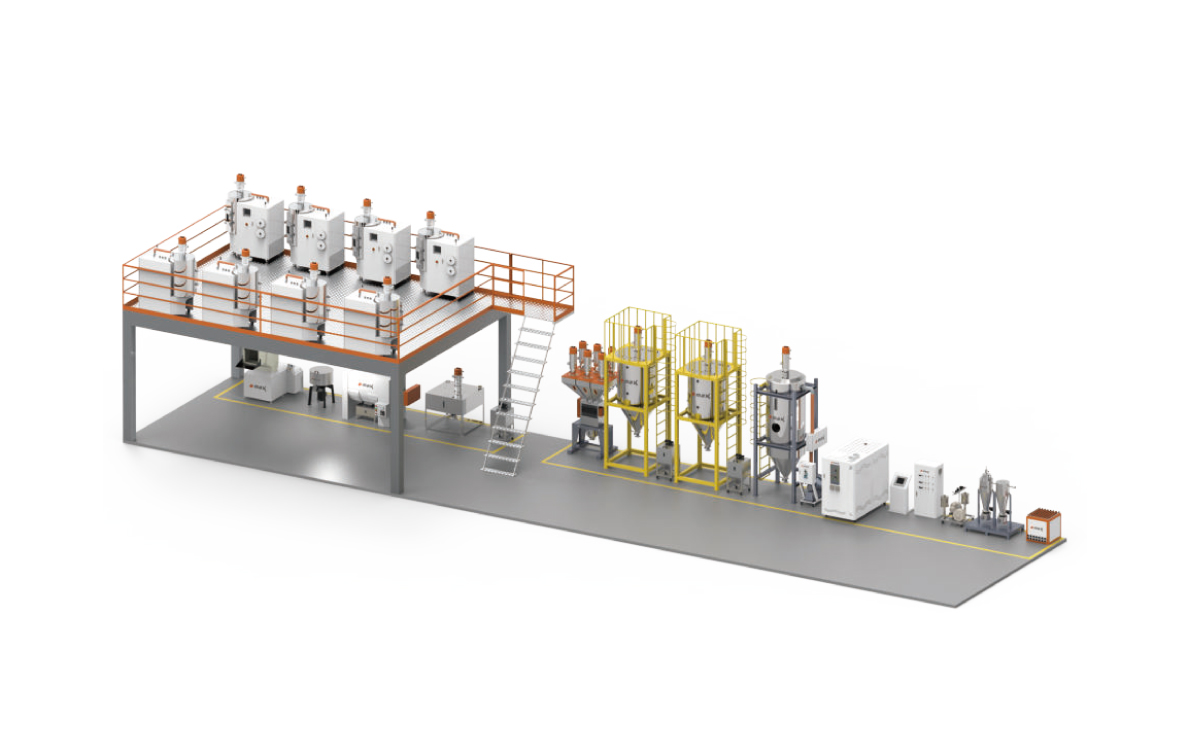

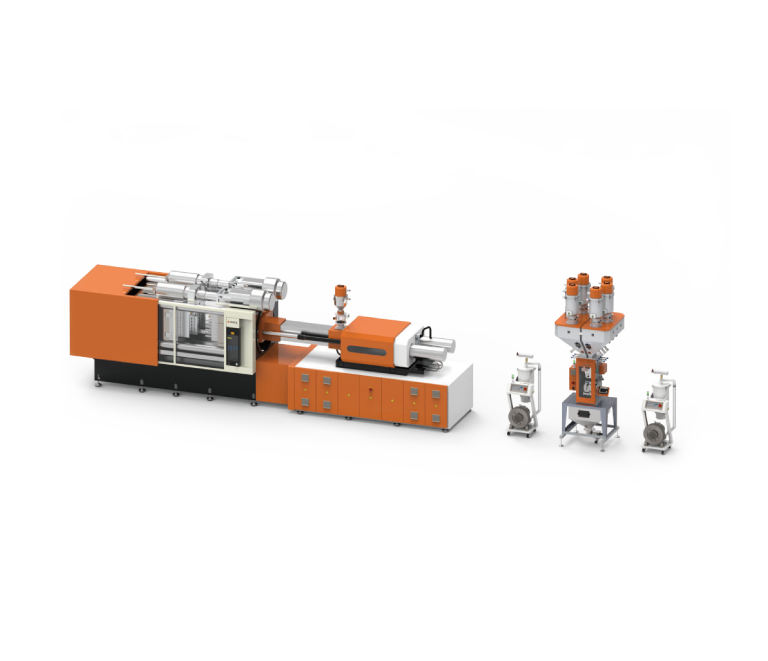

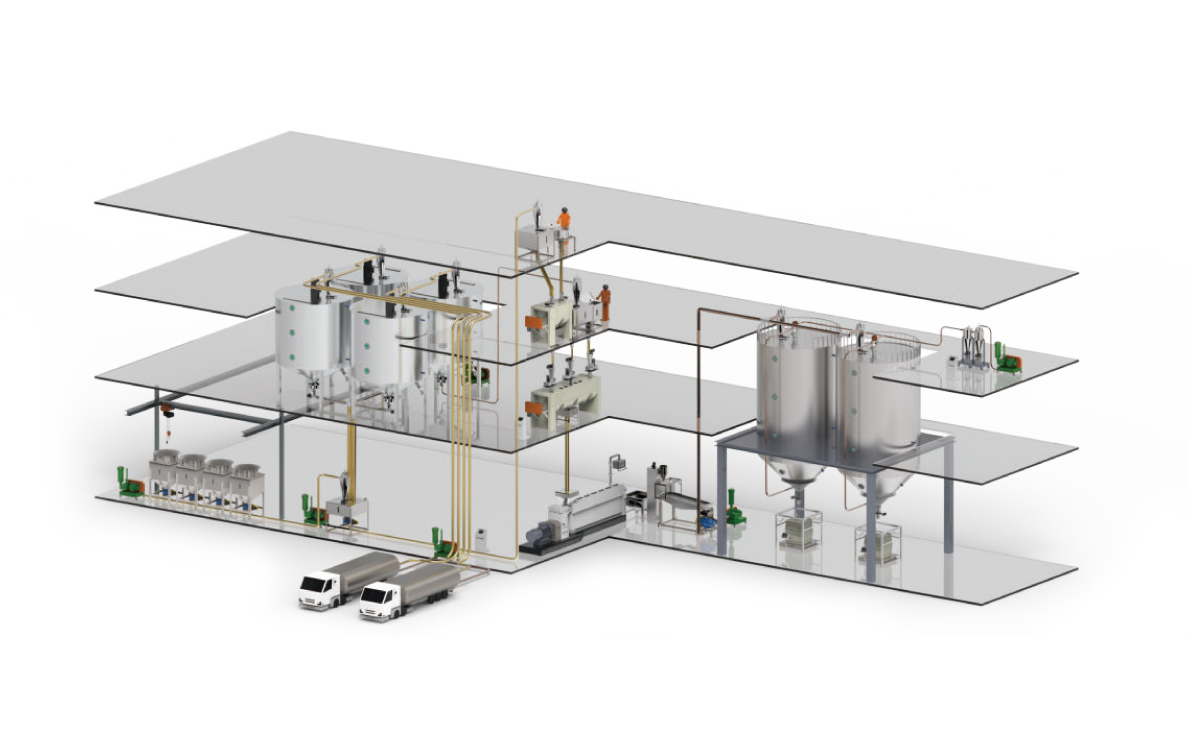

Chemical Plant SiLo, Conveying,Compounding, Dosing And Mixing, Storage, Packaging System